The hot melt glue gun is an important part of hot melt glue machine, Hot-melt glue is as numerous as they are versatile. In general, hot melts are applied by extruding, rolling or spraying, and the high melt viscosity makes them ideal for porous and permeable substrates.in the past blogs, we have introduced the classification of the hot melt glue gun,.Today we want to show you some reasons for the hot melt glue’s working problems in use.

10 Reasons for The Glue Gun Doesn’t Work?

If the glue gun is found to be incapable of being glued during use, please check if the glue gun is hot.

If the glue gun does not heat normally, the reasons may be:

1. the glue gun power supply is not plugged in;

2. the glue gun burned out due to a short circuit.

In the case of normal heating of the glue gun, the reasons may be:

1.the nozzle is blocked by the impurities, it should be handled by professionals;

2. the glue gun is glued to make the strip thicker. At this time, just rotate the strip gently for a week and carefully pull out a small part, peel off the strip and continue to use.

3. Avoid using a glue gun in a humid environment. Humidity can affect the insulation performance and may cause electric shock.

4. The nozzle and the melter are very hot (about 200 degrees). Do not touch other parts except the handle.

5. Never pull out the strip from the glue inlet. Hot melt glue can cause serious burns or damage to the glue gun.

6. Can not be free to disassemble and install its electric heating parts, or it will lead to fault.

7. Do not let children touch it and store it outside its contact area.

8. Do not use any other purpose except molten rubber.

9. If the rubber strip in the glue gun has a backflow phenomenon, please stop using it immediately, and use it after the professional has cleaned the hot melt adhesive.

10. If the glue gun is heated continuously for more than 15 minutes, please turn off the power.

Some products require the entire surface of the coating, and if it is even and thin, it is necessary to use the scraping method. The quality of the squeegee affects the quality of the product, so what will affect the squeegee effect of the hot melt machine?

4 Reasons for The Bad Squeegee Effect:

- The pressure in the hot melt machine is insufficient, and the insufficient pressure can also cause the squeegee effect to be poor, and the machine pressure is adjusted;

- See if the scraper of the scraper is flat, and the scraper of the scraper can adjust the width of the spray and the amount of scraping according to customer requirements;

- Whether the structure of the hot melt glue scraping head is reasonable, the design of the precise and unique curved scraper can greatly improve the working angle of the scraper.

- Whether the glue groove of the scraping head is designed properly, the shape of the glue tank can be adjusted according to the product.

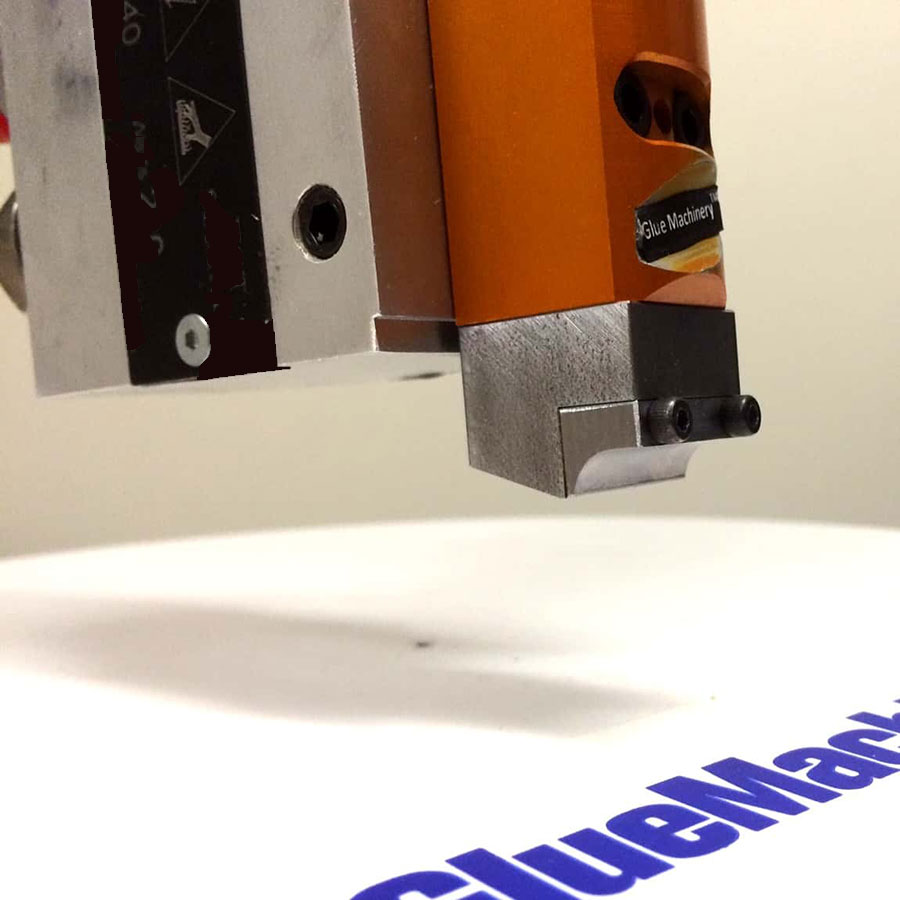

Slot Die Gun

These are all important reasons for the bad squeegee effect of hot melt machine equipment. If you need to know more technology and please leave a comment or contact us!

Now It’s Your Turn

I hoped you enjoyed my detailed information for starting hot melt glue machine business.

Now I want to hear from you:

Which parts from this post are you most excited to know?

Are you going to know more other kinds of related products?

Or do you want to do deep research on this line?

Let me know by leaving a quick comment.