In many adhesives,they produce the product in production line. If they want to prevent their machines from seizing up with glue during production,we can think about the following tips.

1.Choose the right glue machine.

People usually choose the glue machine according to their final product.then how to choose the right glue machine?

Hot melt glue machine is consist of three parts: Glue Tank, Glue Hose, and Glue Gun.

-

About choosing the glue tank.

It depends on the production capacity of your factory or your demands. There are 2L to 50L for the choice.

-

About choosing the glue hose

It depends on the size of the workbench and working distance, the bigger and farther the longer.

-

About choosing the glue gun

It depends on the final products. If for the shoe factory, they need to choose the 2L Double Outputs Hot Melt Glue Machine.

Glue Tank

Glue Hose

Glue Gun

For example, if for the gift box, then they can choose the Three-axis dispenser glue machine. Each action command has an independent glue opening delay, glue closing delay, gun return to the original height, independent pre-closing function, flexible batch modification function can improve editing. So it can help to solve the accumulation problem of glue.

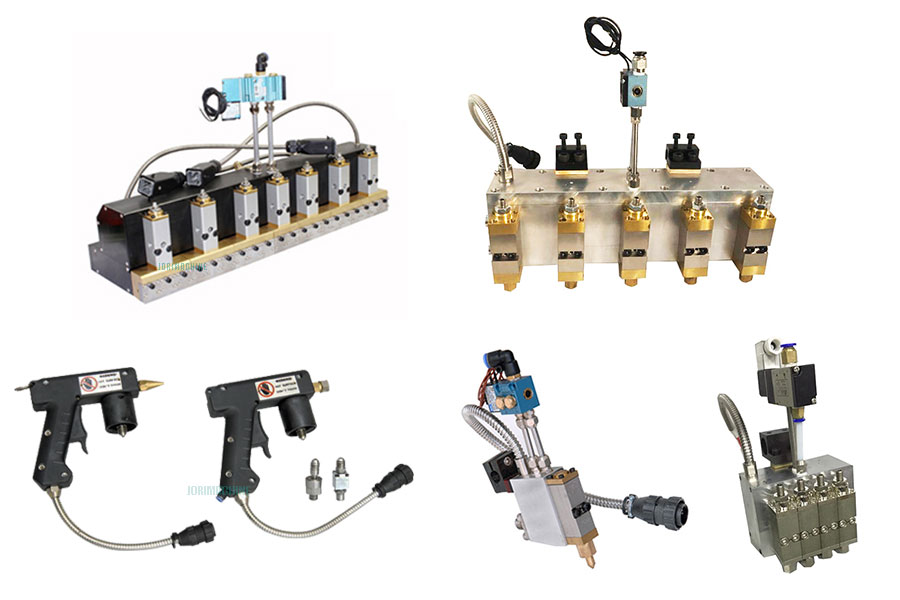

There is many kinds of hot glue gun,handle glue gun,Slot Die Glue Gun,Fiber Glue Gun,Dot Glue Gun(Point Glue Gun)and Special Glue Gun.

Except the handle glue gun,the other guns are controlled by the air pressure,so the amount of the hot glue can be also controlled,in this way,it can prevent the machine from seizing up by the glue.For instance,Pneumatic dispensing gun can be used to complete the glue, glue dispensing, etc. of the product, which not only saves time and effort but also can replace a variety of different types of colloids. The aluminum alloy material is made to make the pneumatic drive glue for a long time, and the output is even.

1)When the hot melt glue machine is not working, the temperature of the rubber tank should be reduced to about 150 °C.

On the one hand, it can avoid the carbonization phenomenon of the hot melt adhesive at the use temperature for a long time, keeping the rubber tank clean and not causing The glue supply system is blocked and the heating performance is lowered.

On the other hand, when the work is resumed, the glue tank can be quickly heated to the use temperature.

In addition, more than 2/3 of the glue must be kept in the rubber can, otherwise black charcoal will be generated around the can.

2)The rubber cans and the rubberized rollers should be cleaned regularly. Excessive carbonization around the rubber cans and residues on the rubber rollers will reduce the performance of the heating system and the glue supply system.

3) If the residual glue in the rubber tank is to be removed before the edge banding machine stops working when the glue is still in the molten state, a T-shaped object is put into the glue, and after the glue is completely cooled, it is reheated. Since the glue at the bottom and the periphery of the can is first melted by heat, most of the remaining glue can be removed with a T-shape. The residual gum was then washed with a 1:1 mixture of toluene and methylene chloride.

Now It’s Your Turn

I hoped you enjoyed my detailed information for starting toilet paper business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.