In addition to meeting the service life requirements of automobiles, the use of hot melt adhesive machines must also have the manufacturability of mass flow production suitable for this,It must have suitable physical and chemical properties and good operation performance, including storage stability,and transportation safety. A car is composed of tens of thousands of parts, mainly composed of a large number of metal and non-metallic parts. Hot melt adhesive is just suitable for the adhesion of this kind of metal material and non-metal material, non-metal material and non-metal material. The hot melt glue machine is easy to operate and can have a variety of gluing methods,such as mist spraying,dot/strip spray,glue roller coating, scraping, fiber gun spray…etc automatic gluing or manual gluing. specific applications in several areas are as follows: The whole inner lining of the trunk is…

Continue Readinghot melt adhesive

What is Hot Melt Adhesive?

Traditional hot melt adhesives (also known as thermoplastic adhesives) are one hundred percent solid, except when heated above a temperature of between 160°C and 180°C. The substance rapidly cools and sets, creating a quick and strong bond. The adhesives can be either very rigid or soft and pliable, depending on what the material is composed of. Hot melt adhesives are compounded from thermoplastic polymers and plastics. They are not affected by moisture, water, or humidity, unlike many other bonding agents. Hot melts are prominently used in the markets of automated manufacturing lines, packaging, converting, footwear, product assembly, bookbinding, and many more. The materials used to make up the hot melt adhesive usually depend on what purpose it will serve. Unlike solvent and water-based adhesives, there is no drying time with hot melt, so its uses are expanding…

Continue ReadingHot Melt Adhesive For Hot Melt Glue Machines

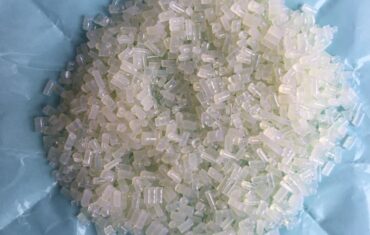

Hot Melt Adhesive For Hot Melt Glue Machines Hot melt adhesive Hot melt adhesives are thermoplastic materials composed of stabilizers, additives, pigments and polymers. They are usually produced by hot melt glue machines and sold as solid, cylindrical rods or pellets. Sticks are melted and applied using a hot melt spray gun or sprayer. Hot-melt adhesive components Hot melts adhesive consists of three main components: high molecular weight polymers, adhesives and plasticizers. Polymer as the main adhesive. Tackifier or resin provides more adhesion and wetting properties. The ability of plasticizers (wax or petroleum) to control viscosity and small machinery is easy to dispense. Advantages of hot melt adhesive The excellent combination of hot-melt adhesives and the application of fast adhesion make hot-melt adhesives particularly suitable for multi-functional packaging applications. Hot melts have a much longer shelf life than solvent adhesives. The…

Continue Reading