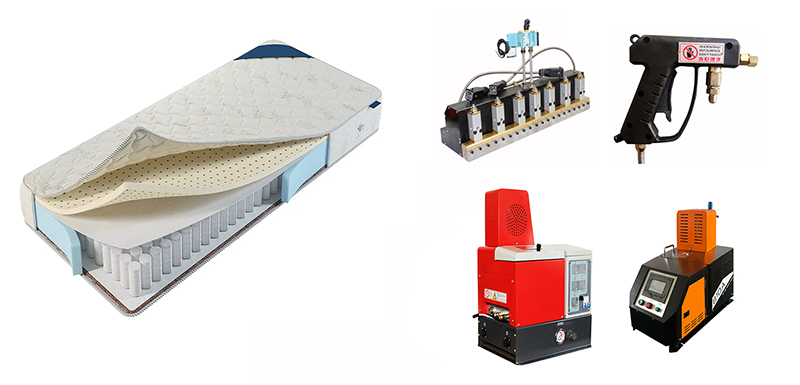

The growing and competitive market environment of the mattress industry demands efficient, flexible, and economical manufacturing processes. JORI is a leading supplier of manual and automatic HOT MELT GLUE MACHINE application solutions in mattress production. Designed for high speeds, fast format changes, and resource savings, the solutions convince through high-quality bonding.

Quality Mattresses for a Healthy Sleep

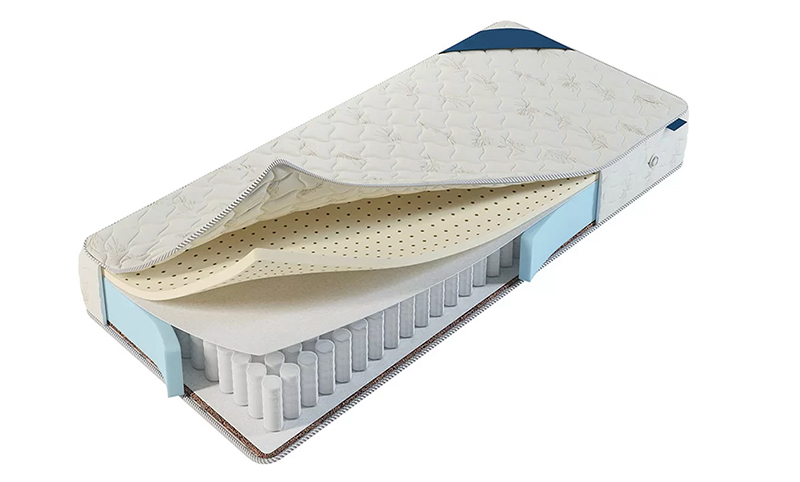

On average, humans spend 6 to 8 hours a day sleeping. No wonder, the bed is the most important piece of furniture in the household. Comfort and quality play a big role when choosing the right mattress. Due to increasing demand and growth in the hotel industry, the mattress industry has become a very dynamic and lucrative market. In addition, online commerce and just-in-time production demand efficient, flexible, and cost-effective production processes without having to compromise on quality.

Thanks to successful cooperation with leading machine manufacturers in the mattress industry, JORI has decades of experience and knows what is important. Whether automatic or manual gluing, slot die gun or fiber gun application, mattresses made of pocket spring, latex or foam cores, we offer suitable solutions.

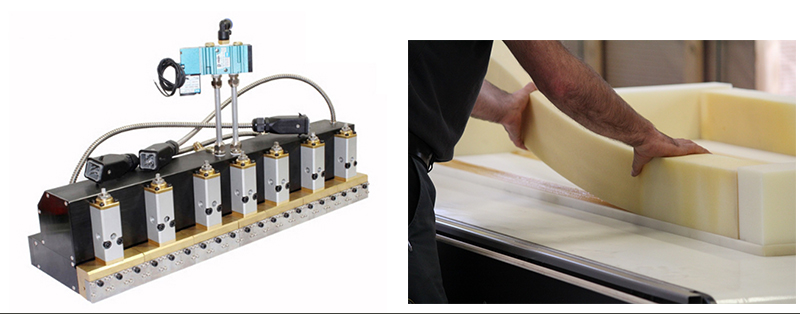

Automatic Glue Machine Application

In a first step, several lines of hot melt glue are applied to the foundation of the mattress using a multi-application head. The outer glue lines are for the frame gluing to which the side padding is attached. The inner adhesive lines are for the mattress core, which is chosen individually according to the type of mattress, e.g., from pocket spring units. The glue lines for the core can be applied in straight lines. If the glue machine application should be even more widespread, a spray head is used. After attaching the side padding and inserting the core, additional foam and padding layers are glued using spray or bead application. Suitable application heads and systems are available, flexibly matched to customer requirements and machine speeds.like use the fiber gun for the mattress .

Manual Glue Machine Application

Hot melt glue handle gun are used in conjunction with a glue machine for the manual gluing process. Depending on the requirements and work step, the handle gun can be provided with nozzles for the mist spray application. To reduce the fatigue of the hand muscles during the adhesive application, the handles are ergonomically adjustable and can be operated without much effort. For an efficient and ergonomically designed workplace, JORI offers special brackets and swivel system for glue machine handle mist spray gun and heated hoses. As a result, several hand applicators can be operated simultaneously from the same hot melt adhesive system.

Now It’s your turn

I hoped you enjoyed my detailed information for starting a business.

Now I want to hear from you:

Which parts from this post are you most excited to know ?

Are you going to know more other kinds of related products? Or do you want to do deep research on this line?

Let me know by leaving a quick comment.